Mega Warehouse Sale!

/Check out our range of various new & used equipment in our Melbourne & Blenheim warehouses, ready to ship immediately!

CEP Beta 40 Crusher Destemmer

MOD BETA-40

Price: A$6000 + GST

This premium destemming and crushing machine is designed for wineries seeking gentle, efficient grape processing with easy cleaning and durable construction. Built entirely from AISI 304 stainless steel, it features self-adjusting food-grade rubber rollers, a stainless steel destemming cage, and a beater shaft with rubber blades.

Whether you’re producing small-batch artisanal wines or expanding a mid-sized operation, the MOD BETA-40 delivers consistent results with a throughput of 3.5–5 tonnes/hour.

Key Features:

Self-adjusting rubber rollers for gentle grape squeezing

Beater shaft with food-grade rubber blades

Stainless steel destemming cage with grooved holes

Fully AISI 304 stainless steel construction

Central opening & cage extraction for fast and easy cleaning

Must collection tray with feed auger

Start/Stop control panel included

Technical Specifications:

Hourly Output 3.5 – 5 tonnes/hour

Motor Power 1.8 kW

Length 1300 mm

Depth 800 mm

Height 1320 mm

Crushing Unit Type Rubber roller

500L Premium Copper Still - Steam Run

Price: A$75,000 + GST

Crafted from premium materials and designed for distillation precision, this 500L jacketed pot still is a versatile, steam-heated system ideal for producing high-quality spirits such as gin, vodka, whisky, rum, and brandy. Built from a combination of AISI 304 stainless steel and copper, it delivers both durability and the unique flavour-enhancing properties distillers demand.

With a copper helmet, bubble cap column, and low-pressure steam heating system, this still is engineered for consistency, control, and maximum spirit purity. Whether you're stripping, refining, or distilling botanical spirits, this still is production-ready and ideal for both new and established distilleries.

Key Features

· 500L capacity copper & stainless steel still

· Jacketed pot design for efficient steam heating

· Constructed from AISI 304 stainless steel and premium copper

· Copper helmet for improved flavour retention and vapor flow

· Versatile use: vodka, gin, whisky, brandy, rum, neutral spirits

· Compact,user-friendly design suitable for commercial-scale craft distilling

· Equipped with agitator, large manway, and CIP-ready fittings

· Sightglass and drain valve on every bubble plate

150Lt Carl Copper Pot Still with Side Column - Used

Price: A$40,000 + GST

The CARL 150L (180lt nominal) Pot Still is a high-quality,German-engineered system crafted for the precision distillation of spirits including gin, whisky, rum, brandy, eau-de-vie, and more. This versatile system features a traditional Cognac-style copper helmet, a 10-plate copper side column, and a Bain-Marie heating system that can be configured for either electric immersion or external steam.

Built with durability and distilling efficiency in mind, this still includes robust temperature controls, integrated safety systems, and a fully CIP-compatible design.

Steam jacket, stainless steel, for efficient indirect heating

Heavy gauge copper pot, hand-hammered and polished, for solidity and longevity

Tubular condenser and distillate outlet, in stainless steel

Cylindrical Helmet and 3 Plate Side Column

Diameter about 680 mm / 26.75 in made of thick copper plates = min. 3.5 mm

Spherical form, hammered

Upper part of the copper boiler (still head), about 450 mm / 17.75 in high, vaulted

Key Features:

Net Capacity: 150L pot still with DN 680 opening

Copper Helmet: Cognac-style design for optimal flavour and reflux

Side Column: 10 copper bubble cap plates with observation and lighting ports

Heating Options: Indirect Bain-Marie via immersion heaters or steam jacket

Material: Copper pot, helmet, and column; stainless steel for pipework and condensers

Reflux Condenser: Integrated dephlegmator with water cooling and copper cladding

CIP Integration: Includes spray balls and welded stainless steel manifolds

Spirit Outlet: Glass spirit port with hydrometer

Agitator: Ex-proof, slow-speed 1.1 kW motor-driven agitator(optional)

300Lt Electric Copper Distillation System

Price: A$55,000 + GST

Designed for both craft and commercial distillers, this 300-litre indirect-heating electric still is the perfect solution for producing high-purity spirits including vodka, gin, whiskey, and eaux-de-vie. This copper-based distillation system combines modular flexibility with high-performance features to help elevate spirit quality and production efficiency.

Key Features:

300L copper pot with indirect electric heating

Designed for vodka, gin, whiskey, and other premium spirits

Modular system enables flexible configurations and multi-functional spirit productionFine distillation columns optimized for flavour preservation and separation

High-performance rectification columns can achieve up to 96% ABV purity

Copper catalytic converter reduces acids, cyanide, and ethyl carbamate

Integrated high-pressure rinsing system for internal CIP cleaning

Three-way ball valve allows seamless switching between different spirit types

Enhanced copper contact surface for flavour development and sulphur removal Customizable distillation runs for a variety of product styles

Ideal for craft gin distilleries, boutique spirits, and micro-distilling.

Automatic 4-side Sachet Packaging Machine

Price: $80,000 + GST

The FOFS-4W-2L-500 is a fully automatic, high-speed sachet packaging machine designed for powder, granules, liquids, and other single-dose applications.With twin lanes, integrated auger dosing, and easy-tear sachet technology, it’s ideal for electrolyte powders, nutritional supplements, and pharmaceutical packaging.

This robust system features touchscreen programming, tele-assistance connectivity, and tool-free format changes, making it a perfect solution for producers seeking speed, flexibility, and precision.

Dosing & Add-ons (Included)

Volumetric auger dosing system with agitator

Dust extractor for dosing and forming area

Clamps/shutter system to prevent leakage during dosing

200L auger feeder with sieve and hopper cover

Automatic diverter chute for sachet rejection

Flap diverter for carton filling

Tele-assistance VPN-ready module for remote diagnostics and PLC logic updates

Marker-ready software interface for twin-head inkjet printers

Ideal Applications

Electrolyte and supplement powders

Nutraceuticals and oral rehydration salts

Spices, instant coffee, or drink powders

Creams, pastes, and gel formulations

Pharmaceutical and diagnostic powders

Available for integration into new or existing production lines

Liquid Pouch Filler with Spout Application (New)

Price: $120,000 + GST

A complete automatic pouch filling and spout capping system, the FOFS-R8-040A is engineered for clean, reliable filling of stand-up pouches with optional inert gas injection and full wash-down configuration. Ideal for juices, sauces,oils, dairy products, and more, this compact rotary system includes dosing,sealing, spout feed, and pouch handling in a hygienic, all-in-one solution.

Key Features:

Rotary 8-station carrousel system with pneumatic pouch grippers

Compatible with liquid or semi-liquid products (100–500 mL)

Works with a variety of pouch types and material combination

Equipped for inert gas injection (1- or 2-point)

Ultrasonic or hot blade sealing options

Stand-up pouch opening system with air and suction cup assist

Modular accessories for full customisation

Wash-down configuration for wet/corrosive environments

Each pouch is carried securely from start to finish via individual clamps.

Filling Volume: 100 – 500 mL

Construction: AISI 304 / 316 stainless steel

Product Types: Liquid / semi-liquid

Dosing Type: Pneumatic volumetric

Dosing System: Volumetric piston with PTFE seals

Hopper Size: 50L (optional external hopper available)

Pouch Types: Stand-up, spouted, custom formats

Spout Handling: Vibratory feeder with insertion & sealing unit

Sealing Method: Ultrasonic or hot blade (depending on configuration)

Gas Injection: Optional 1- or 2-point inert gas system

Print Capability: Inkjet printer mount (optional)

Electrical Cabinet: IP65 wash-down rated

Drainage & Hygiene: Sloped base, drain channel, elevated cabling

Modularity: Optional mobile dosing unit and accessories

Output Capacity: Up to 10,000 pouches/hour (based on format and dose)

50Lt Distillation Unit - New

Price: $2800 + GST

50L home still is ideal for small batch distillation and intended for recipe development of all types of alcohols. A column with bubble cups allows doing rectification process.

Additional Copper helmets are ideal for pot still distillation mode that is suitable for traditional whiskey, brandy, or rum production, they offer a larger surface for interacting with the vapor.

The kettle is made from a 2mm wall of 304 food grade stainless steel

220V-240V single phase 50HZ

Power rating is 10KW

Comes with four red copper bubble plates which can be removed or more added depending on how refined you want your end product.

Comes with a side spirit collection arm and a drainage valve at the bottom of the tank

The columns clip off for easy access to the tank and for cleaning

The heating element in the tank is in direct contact with the liquid. This makes it quicker to boil but does mean you cannot run these units dry.

Makes any spirit, essential oil or distilled water you want depending on your starting base.

Automatic Coffee Pod Production & Packaging Line

This state-of-the-art, fully automatic coffee pod production line is engineered to seamlessly handle the entire process—from grinding coffee beans to packaging pods into distribution cartons. Designed to accommodate various capsule types, including compostable materials, this system ensures flexibility and efficiency for modern coffee production needs.

Can be purchased as a whole line or just the individual components.

Price: POA

Pod capsule hopper infeed to the automatic pod elevator and orientation to the outfeed conveyor feeding the coffee pod and foil application bloc. This solution provides long run autonomy with labour usually required to hand load andorientate capsules to the pod filling unit, this monobloc only requires cartons of pod capsules to be thrown into the loading hopper.

Price: POA

Colombini coffee grinding unit with coffee bean vacuum suction set. Colombini as a manufacturer of coffee grinders is very highly regarded in respects to industrial level coffee grinding, globally. The coffee grinding unit is set on a support structure to either grind into the filling unit directly, or the set enables the grinding unit to be rotated and operated as a stand-alone grinding unit, with ground coffee moved to silo storage. Coffee can be mobilised from Silo’s to the Coffee Pod and foil packaging machine separately.

Price: POA

The Coffee pod rotary filling with dosing, fully automatic PLC with recipe control, comes with many features, including electronic weight checking and reject system inline so that QA is performed pre carton packing. The system has a dual foil roll feed to enable long run autonomy operation, saving on machine down time and labour hours lost.

Price: POA

The back end carton forming and erecting monobloc with the Nordson carton hot melt glue unitis state of art robotics. The carton formats can be varied for 10 x 1 pod format sticks or 2 x 5 or 3 x 4 carton formats.

Camurri Brauer CB.400 Dual Module Brewing System

ONLY $6000 + GST

The CAMURRI BRAUER CB.400 is a fully integrated, patented brewing unit designed for hand-crafted beer production using all-natural ingredients. Built entirely from AISI 304 stainless steel, this dual-module system simplifies the hot-extraction process and delivers exceptional flexibility and performance for small-scale brewers.

Key Features

· Dual Independent Modules: Two 200-litre tanks allow for separate or simultaneous operation.

· PLC-Controlled Automation: Each module includes a programmable logic controller with BT interface for Android tablet/smart phone control.

· Efficient Heating System: Three built-in elements per module maintain optimal process temperatures throughout the brewing cycle.

· Integrated Mixer: Gear-driven mixing ensures proper blending for optimal aroma and flavour extraction.

· Stainless Steel Double-Mesh Filter: Durable and easy to clean.

· Mobility & Safety: Includes 4 casters (2with brake) and 2 adjustable feet for stable operation.

· User-Friendly Filter Lifting: Integrated winch with lifting spider simplifies handling and cleaning.

· Comprehensive Accessory Compatibility: Supports fermentation tanks, hop filters, heat exchangers and more.

Stagionello Cheese Maturation Fridge

Price: $27,000+GST

Italian-made Stagionello Climatouch fridge for cheese maturation.

Second hand and in full working order. Slight dent on the top in the centre that does not affect the working of the unit.

Affinacheese® is specifically designed for the drying and seasoning of various types of cheeses. All internal and external components that come into contact with food are made from AISI 304 stainless steel. Climatouch® is an advanced management system that creates the ideal microclimates required for food transformation. This system automatically manages the creation of these microclimates using preprogrammed climatic recipes or custom recipes stored in internal memory.

Model: STGTWIFFO

Voltage: 230V

Frequency: 50HZ

Max Power: 3212W 14,6A

Heaters: 704 WX2 3,2A x2

Air Recycling: 110+44W 0.5 + 25

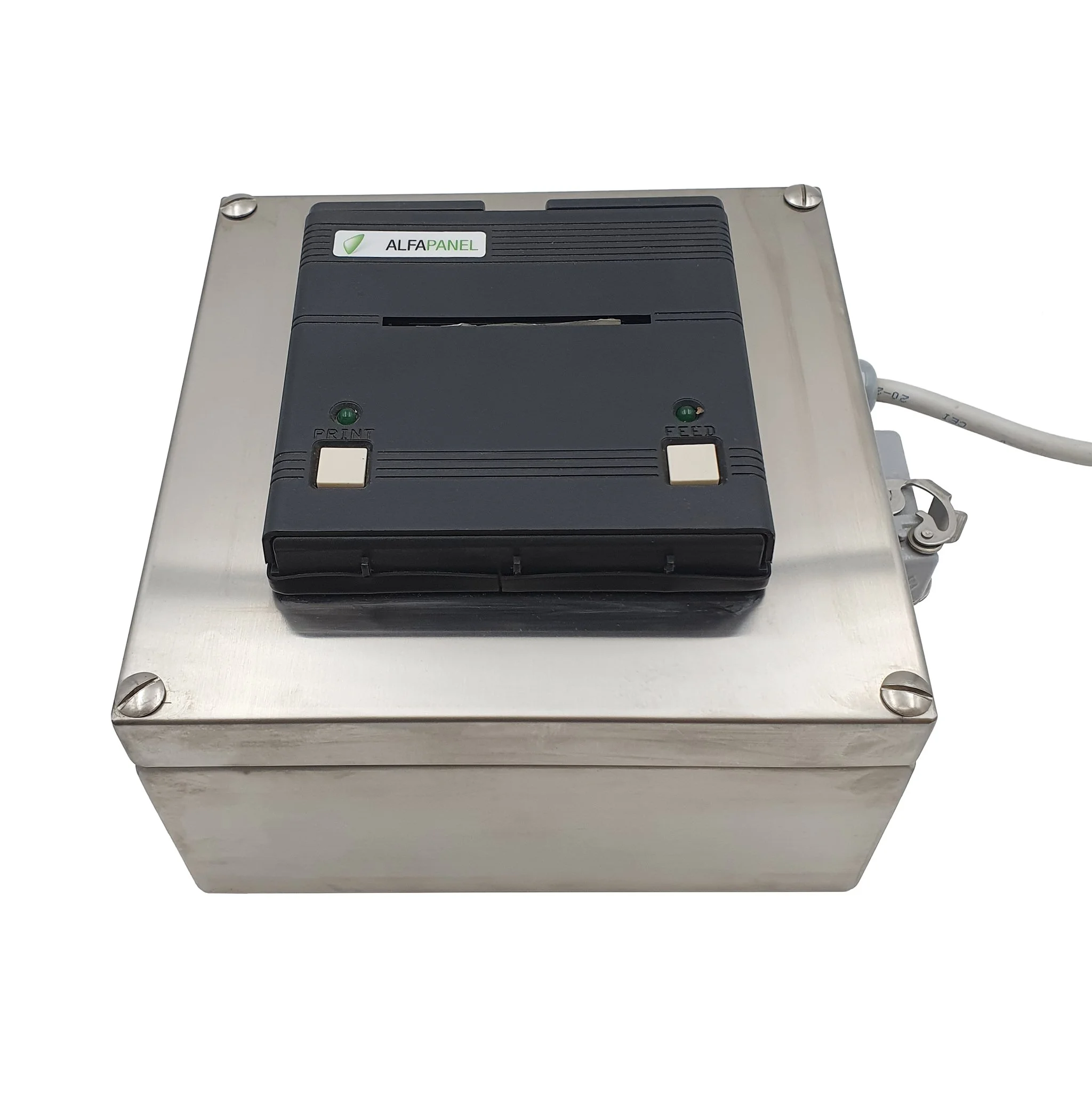

Alfa Panel Data Printer

PRICE: $2600+GST

Compact and easy to install.

Has a front panel that can be opened to replace the cartridge

Control of different alphanumeric print-formats, combinable with one another.

Most common communication interfaces are supported

USED: Curd Drain Cart

PRICE: $3500+GST

Stainless steel moveable trolley for the drainage of whey. Mobile with nylon wheels, brake and ball valve tap.

Italian made

External Dimensions:

Height: 67cm

Width: 64cm

Length: 82cm

Internal Cart Dimensions:

Height: 25cm

Width: 58cm

Length: 78cm

Red Wine Vinegar System 500Lt

With dual acetifiers and temperature control

PRICE: $10,000+GST

High-quality acetification system with dual 500L stainless steel tanks for continuous vinegar production.

Designed for industrial producers looking for an efficient, hygienic, and semi-automated solution to convert wine into vinegar using the traditional aerobic method — enhanced with precision temperature control and stainless steel construction.

Fermentation Process

Load wine (10% ABV) into the tank via manhole or top inlet until resistance is submerged

Activate mixer to oxygenate the wine

Heating element warms the wine to the ideal temperature (28–32°C)

Natural heat from fermentation is regulated by built-in cooling jackets

After fermentation, vinegar is extracted while maintaining 30–50% tank volume

Top up with fresh wine, and the cycle begins again

Key Features

· Two x 500L tanks made from AISI 304 stainless steel for durability and hygienic processing

· Continuous fermentation method with oxygenation and temperature-controlled cycling

· Built-in aeration mixer to stimulate acetic fermentation

· Electric heating resistance ensures optimal fermentation temperature

· Cooling jackets automatically regulate internal heat generated by exothermic fermentation

· Can operate tanks individually or in series

· Top manhole and roof inlet for easy wine filling

· Integrated control panel for mixer and heating regulation

· Fully cleanable and sterilizable design

225Lt Garbellotto Oak Barrels

Price: $1000 + GST each

Medium, sweet or strong toasted

Made from top quality European Oak

La Inox Variable Capacity Tank

Price: $1000 + GST

Italian made stainless steel flat bottom tank for storing wine. Can be used for other liquids such as beer, cider and olive oil. The floating lid adjusts to varying levels of volume to keep out air during secondary fermentation and bulk ageing.

Included:

Lid, airlock, hand pump, inflatable seal, rope, hose and clamp.

Maurer Belt Press (NZ Stock)

Was $19,840 + GST

NOW $15,000 + GST

Fully automatic operation, with closed work area, reduces the oxidation to the minimum. In the bottom of the machine, there are two spinning washer heads guarantees optimal cleaning during the process. The distance between the press cylinder and the juice collector tray reduced against foaming. Very easy to clean. Mounted on 4 each Anti-vibration feet. Requires minimal maintenance.

Specifications:

• Performance:1400 kg/h

• Electric demands: 3 kW, 400 V, 6 A, triphase

• Material: WNr. 1.4301, AISI 304 stainless steel

• Dimensions: 2700x1550x1250 mm

• Input height: 1250 mm

• Output height: 370 mm

• Weight: 1150 kg

• IP65 certified electronics

• Food industrial, massive polyester belt

• High yield: 75% – depends on the freshness and quality of the fruits

• High-pressure washer demand: 500 L/h

• Compressed air demand: 50 L/h 6 bar

• Built-in inverter: stepless adjustable belt speed

Maurer Fruit and Vegetable Washer Belt with Brusher and Grinder (NZ Stock)

Price: $9019.00 + GST

The fruits goto the input hopper, after soaking the elevator towards the fruit under the secondary clearwater sprays. Easy to clean, with massive polypropylene/acetal modular elevator, stepless adjustable speed in both ways, with 2pcs rotating, 2pcs fix wheels or vibration-free feet. Requires minimal maintenance.

Technical data

Performance:3000 kg/h

Power: 5 kW, 400 V, 16 A, 3 phase

Weight: 360

Size: 3660x 2120 x 950 mm

Technical details:

Performance: 3000 kg/h

Electric demands: 5 kW, 400 V,16 A

Material: Wnr. 1.4301, AISI 304 stainless steel

Weight: 360 kg

Tub water capacity: 440 L

Washing water supply: 100-200 L/h (depending on the setting)

Water connection: ¾” quick connector

IP65 certified electronics

Grinder with a massive crushing hammer (available for beetroot and quince))

The grinder can be by-passed and turned, this way the machine is capable of process stone-fruit

Noise emission: 60-70 d

4 pcs of strong, counter-rotating brushes for the intense cleaning

Rotating paddle, that towards the washed fruit to the elevator

Requires minimal maintenance

Adjustable belt speed

Vertical Hydraulic Press SIRIO 100

+ Trolley (NZ Stock)

Price: $35,000 + GST

Automatic Vertical Hydraulic Press with two motors and control panel with fast approach push button.

Vertical automatic hydraulic press developed to valorise the grape pressing quality

Bearing frame in high-resistance steel

New structure of Modern Design, mounted on wheels

Painted steel trolley on wheels, with manual pump and tank lifting cylinder

Wine must collection tank in stainless steel Aisi 304

Notches on press in stainless steel Aisi 304

Control panel with Fast Approach push-button

Double hydraulic pump with double safety valve

High pressure pump, Electrical components and valves by World Leading Manufacturer

Electric contact pressure gauge with automatic reset of the set pressure

Pressure variable from 50 to 350 bar.

Power kw 1.1+1.1 V.400/50Hz. Three-phased

Cage: Dia Ø. 1000x Height 1000h mm

Capacity 900 l. for cage

Framax Warming and Cooling Tunnel

Price: $80,000 + GST

Efficient Can Warming with the COOLER 1.5 x 7.5 E

The COOLER 1.5 x 7.5 E by Framax is a high-performance can warming tunnel engineered for beverage production lines. Designed with a stainless steel frame and managed via PLC automation, this system delivers consistent heating results. It processes up to 185 cans per minute, raising product temperature from 35°C to 72°C over a 12-minute cycle. With a conveyor height of 1100 mm(±50 mm), total usable area of 12 m², and steam consumption of 850 kg/h at 3bar, it combines reliability with efficient thermal transfer. Operating on 415V50Hz 3-phase power, it's built for rigorous, continuous production environments.